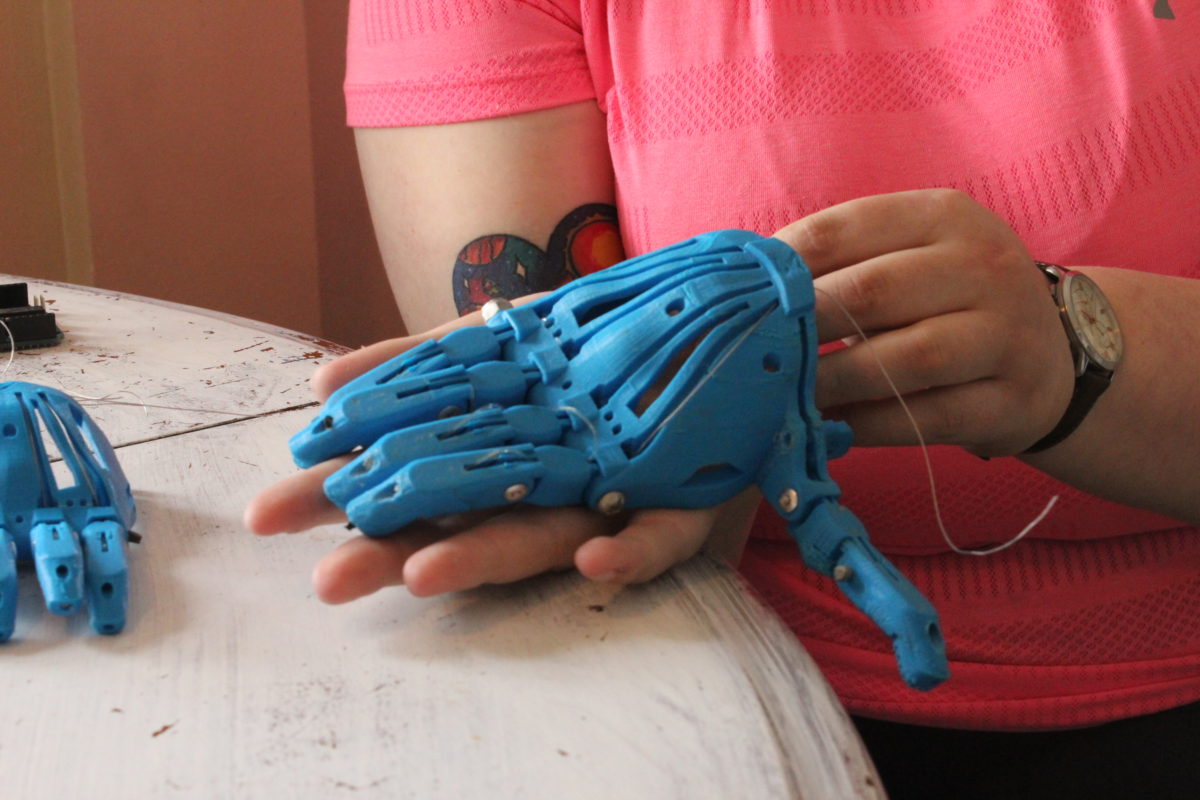

A typical afternoon for Cassandra Pitchford involves sitting at her kitchen table in the upstairs of an old house on York Street and working on a prosthetic hand.

The third-year University of New Brunswick student loves to make people laugh. She loves her mom’s dogs, Roxy and Jena. She said she’s good at making a fool of herself. But Pitchford is also compassionate, hardworking and “loves a good bubblebath with a glass of wine.”

And she’s on a path to transform the lives of people in need of prosthetics.

When Pitchford’s Grade 12 physics teacher talked to the class about 3-D printing, she was instantly captivated.

“It all started right here three years ago,” she said, lifting up the small blue prosthetic hand she built in Grade 12.

Pitchford realized she wanted to work with prosthetics when she was listening to a story from her grandmother.

“She was telling me a story about how her sister — she is a below-the-knee amputee — how she was having trouble walking because her prosthetic was no longer fitting properly because it was just really old,” Pitchford said.

Pitchford’s great aunt had few options: she could use a wheelchair, buy a new prosthetic or if the cartilage damage became too extensive, the doctors would have to amputate above the knee.

“So, I was kind of thinking, ‘Let’s change that.’”

Her interest in prosthesis grew from there. When she first saw one of the fingers on the hand she built move, she knew what she wanted to do in life.

“When that finger moved, the lightbulb went off. This is real. I can make my dreams a reality — helping people to have access to more affordable prosthesis because no one should have to look in the mirror and think of a Disney villain when they can have something like this,” she said, holding the hand.

And now Pitchford’s working on her own prosthesis design.

“I have a lot of amputees in my family, so I’m no stranger to how much of a burden, both financially as well as emotionally, prostheses can be.”

Protheses are expensive and the New Brunswick Medicare program doesn’t cover them.

Pitchford said basic non-prosthetic hands start at about $1,000, but ones that move cost around $5,000.

“Being in a poor province where a lot of us don’t have the luxury of third-party health insurance … There’s no solution,” she said.

So she decided to combine 3-D printing with an already existing technology called myoelectricity and build her own prosthetics for others.

Myoelectricity uses a muscle sensor. When the muscle is flexed, a voltage is picked up by the sensor. It goes to a micro-controller. When the voltage reaches the micro-controller, it tells the motor to move, which causes the fingers to clench.

Pitchford said mechanical prosthetics help give people their lives back.

“There’s a humongous psychological aspect to losing a limb — with the phantom pains, with looking in the mirror and it’s just not there anymore or you wake up in the middle of the night and you move and you realize it’s gone, and it’s the weirdest thing in the world,” she said. “To give them something to say, ‘Okay, with this you can hold a cup again.’ It helps give them their independence back and it helps boost self-confidence as well.”

Pitchford said having members of her family with disabilities brings the work she does closer to home.

“It gives me a real goal … No one in my family needs an upper limb prosthesis [which is what I make], but it’s to make them proud,” she said. “And for them to say, ‘Look, my granddaughter made this, my niece did this.’”

Pitchford lives with a disability too, and it has inspired her to help others.

“I’m not learning all of this fancy-shmancy physics and math and going through all of this pain to get myself a nice big paycheque at the end of the day. No, I want to use my knowledge to make other people’s lives better because that in turn will make my life better.”

In 2011, she went for a routine audiogram and discovered she has a gene that’s causing her to go deaf. In noisy environments, she has to rely on lip reading. Pitchford doesn’t process auditory information the same way others do. She has to focus on the actual words, as opposed to focusing on the content.

She said if there’s one thing she wants people to know about her, it’s that she’s a fighter.

She has a tattoo on her forearm that reads “Strong” in sign language. She said it’s a conversation starter and a declaration of her strength.

“It represents all of the battles I’ve had to fight to get to where I am today … It’s for every single person who has told me, ‘What engineering firm would hire someone like you?’”

Pitchford says the way she interacts with the world around her has changed since she lost her hearing.

“I’ve had to make my voice even bigger since I lost my hearing,” she said.

People have asked her how she could be deaf if she “sounds normal” and why she doesn’t just get a cochlear implant. One person even asked her how she still has her ears.

“You constantly have to educate people,” she said. “Now that I’m a member of the deaf and hard of hearing community, I need to be a voice for those who choose not to use theirs and I’m helping bring an entire community up.”

She said people will often say they’re “so sorry” she’s deaf.

“I’m not sorry,” she said. “It has made me into who I am today.”

She said it’s made her more patient, kind and taught her to never give up.

Pitchford’s work also led her to be a leader for girls who want to pursue STEM careers. She’s currently building a robotics program at Nashwaaksis Memorial School that’s going to start in the next few weeks.

Although she may not pursue a masters degree, she plans to continue her work on prosthetics.

“I want to continue making this a reality. I want this to be available to any person in Canada, the [United States], maybe even take it overseas,” she said.

“If I can just help one person with this prosthetic, with this design, then it’s a success.”